It is supplied as a two-part material in pre-weighed quantities ready for onsite mixing and use. SAFETY DATA SHEET Nitobond HAR SDS.

27 August 2015 Version.

Nitobond ep hardener sds. Nitobond EP Base PROPAN-2-OL 1 CAS number. FOSROC NITOBOND EP HARDENER SDS No. NITOBOND EP HARDENER Application.

Product Name FOSROC NITOBOND EP HARDENER Classified as hazardous H312 Harmful in contact with skin. Nitobond HAR TECHNICAL DATA SHEET Nitobond HAR TDS. Nitobond EP may also be used as part of a repair system where a substraterepair barrier is required or where the substrate is likely to remain permanently damp or wet.

4 - 5 mlitre. 2 - H319 STOT SE 3 - H336 The Full Text for all R-Phrases and Hazard Statements are Displayed in Section 16. 1 and 4 litre packs.

Hardened material can only be removed mechanically. The minimum application temperature for Nitobond EP is 5C. Coleshill Road Tamworth Staffordshire.

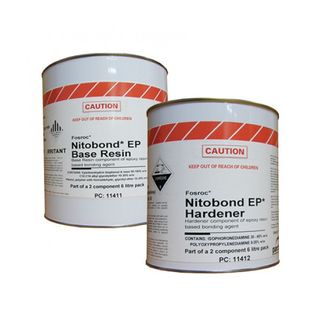

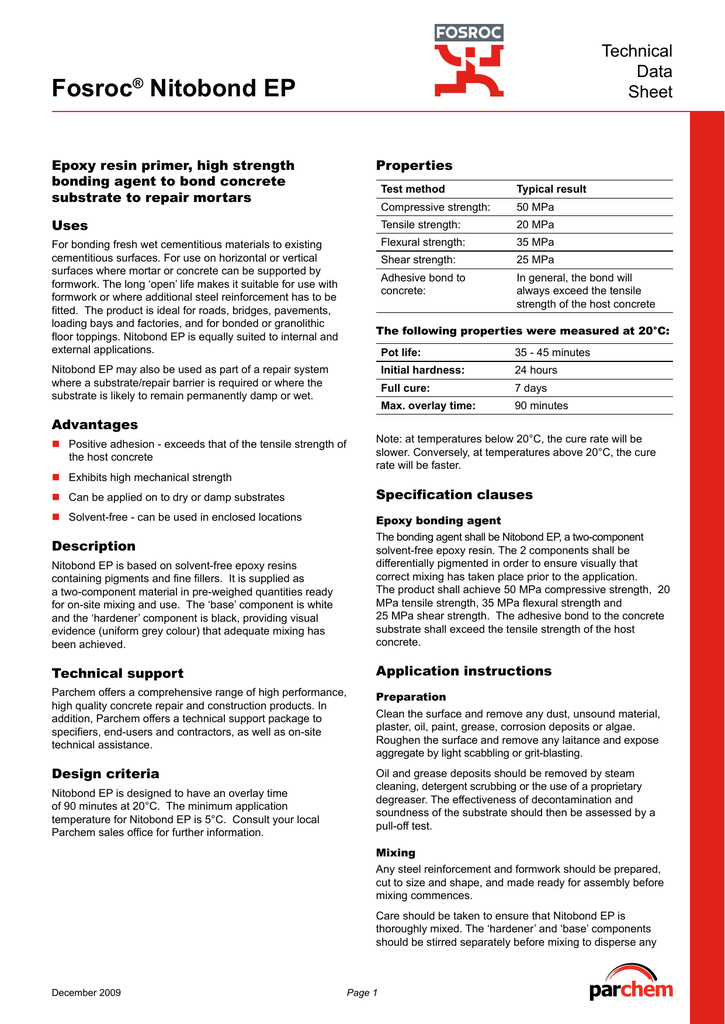

Specification clause Epoxy bonding agent The bonding agent shall be Nitobond EP a two-component solvent-free epoxy resin. Hardener component of epoxy bonding agent system. Nitobond EP is designed with an overlay time of 12 hours at 35C and 5 hours at 45C making it more suitable for use where additional steel reinforcement and formwork has to be fitted or where temperatures are high.

Nitomortar EL-HB Hardener 9L Pack. If any doubts arise concerning temperature or substrate conditions consult your local Parchem. Coleshill Road Tamworth Staffordshire.

Limitations Nitobond EP should not be applied when the temperature is below 5C or is 5C and falling. Nitobond EP is suited to internal and external applications. Nitobond EP is a 2 component epoxy bonding agent for bonding fresh wet cementitious materials to existing cementitious surfaces.

1 of 8 Hazardous Substance Dangerous Goods 1. Nitobond EP Base SDS Nitobond EP Hardener SDS. H314 Causes severe skin burns and eye damage.

Consult the local Fosroc office for further information. 15 and 60 litre packs Fosroc Solvent 10. MATERIAL AND SUPPLY COMPANY IDENTIFICATION Product name.

Base component of epoxy bonding agent system. H372 Causes damage to organs through prolonged or repeated exposure. Applied by brush or roller.

Nitobond EP is designed to have an overlay time of 90 minutes at 20C. Hardener component of epoxy bonding agent system. Coloured components white base and green hardener provide visual evidence that adequate mixing is achieved.

The base component is white and the hardener component is green providing visual evidence that adequate mixing has been achieved. 4 and 20 litre pails Coverage Nitomortar EL-HB Each 9 litre pack will cover approximately 09m2 at 10mm thick Nitobond EP. H350 May cause cancer.

COMPOSITIONINFORMATION ON INGREDIENTS 32. 2 - H225 Eye Irrit. FOSROC NITOBOND EP HARDENER Recommended use.

13860円 その他 パソコン周辺機器 CanonDR-M160ADFドキュメントスキャナー高速 中古 Canon DR-M160 A4 高速ADF両面読込 毎分60枚高速読み込み ドキュメントスキャナー b7810. Nitobond SBR TECHNICAL DATA SHEET Nitobond SBR TDS. Modified aromatic amine.

COMPOSITIONINFORMATION ON INGREDIENTS Composition. FC342255-920ML Nitomortar EL-HB Fillers 9L Pack. NITOBOND EP SLOW SET HARDENER Application.

TALL OIL FATTY ACIDS 60-100 CAS. The minimum application temperature for Nitobond EP is 5C. Coleshill Road Tamworth.

Hardener component of epoxy bonding primer. Resapol Ltd D4 Moss Industrial Estate Leigh Lancashire WN7 3PT. Make sure to remove any contact lenses from the eyes before rinsing.

Consult your local Fosroc sales office for further information. It is supplied as a two-component material in pre-weighed quantities ready for on-site mixing and use. The 2 components shall be.

NITOBOND EP HARDENER S60 This material and its container must be disposed of as hazardous waste. NITOBOND EP BASE Eye Contact Remove victim immediately from source of exposure. Promptly wash eyes with plenty of water while lifting the eye lids.

Nitobond EP is supplied as a two-component material in pre-weighed quantities ready for on-site mixing and use. H318 Causes serious eye damage. Mixtures POLYMER OF C-18 UNSATURATED FATTY ACID DIMER WITH TRIETHYLENETETRAMINE.

SAFETY DATA SHEET Nitobond SBR SDS. Continue to rinse for at least 15 minutes and get medical attention. The base component is white and the hardener component is green providing visual evidence that adequate mixing has been achieved.

0800 276 1599 All Other Enquiries. 01827 262222 Out of Hours. Most important symptoms and effects both acute and delayed.

Nitobond EP should be removed from tools equipment and mixers with Solvent 10 immediately after use. Other hazards Not Classified as PBTvPvB by current EU criteria. H317 May cause an allergic skin reaction.

Nitobond EP is based on solvent-free epoxy resins containing pigments and fine fillers.

Nitomortar El Method Statement Parchem

Nitomortar El Method Statement Parchem

Fosroc Nitobond Ep Tds Manualzz

Fosroc Nitobond Ep Tds Manualzz

Fosroc Nitobond Ep Constructive Solutions Parchem Fosroc Nitobond Ep Constructive Solutions Parchem Pdf Pdf4pro

Fosroc Nitobond Ep Constructive Solutions Parchem Fosroc Nitobond Ep Constructive Solutions Parchem Pdf Pdf4pro

Fosroc Nitobond Sbr Sds Aus And Nz Manualzz

Fosroc Nitobond Sbr Sds Aus And Nz Manualzz

Https Go Lupinsys Com Duluxgroup Harms Public Materials B991eaac1c5651803f25438509534b8a Published Attachments Api A317d731cb4e3b43ad24816468549053 Search Api Fosroc Nitobond Ep Hardener Nz Sds Pdf

Fillable Online Nitobond Ep Epms Supplies Fax Email Print Pdffiller

Fillable Online Nitobond Ep Epms Supplies Fax Email Print Pdffiller

Nitomortar El Method Statement Parchem

Nitomortar El Method Statement Parchem

Chemical Grade Nitobond Ep 4 Ltr 1 Ltr Packaging Type Box Rs 3650 Unit Id 9870122548

Chemical Grade Nitobond Ep 4 Ltr 1 Ltr Packaging Type Box Rs 3650 Unit Id 9870122548

Fosroc Nitobond Ep Base Sds Aus Manualzz

Fosroc Nitobond Ep Base Sds Aus Manualzz

Fosroc Nitocote Ep405 Hardener Sds Nz Manualzz

Fosroc Nitocote Ep405 Hardener Sds Nz Manualzz

Http Www Fosroc Com Api Safetysheets 95 1